5a.

Manufacturing – sustainable production

Factory smokestacks. Kunda, Lääne-Viru county, Estonia 1993. CC Photo: Curt Carnemark / World Bank

Factory smokestacks. Kunda, Lääne-Viru county, Estonia 1993. CC Photo: Curt Carnemark / World Bank

In its beginning industrial production was connected to chimneys with dirty smoke, effluents to rivers and mountains of bad-smelling solid waste. This has been improved over the years but still in the end of the last century industrial production caused much pollution. This is obviously not sustainable and has to change. An equally important aspect is the resource use in industrial production, may it be metal ore, biomass such as wood, or the large amounts of energy, quite often fossil. In contrast sustainable production deals with how to improve and manage production in a manner which is resource efficient, non-polluting and produces products which themselves are environmentally friendly and sustainable.

The importance of developing sustainable production and consumption patterns cannot be overstated. It was singled out in the 1992 UNCED Rio conference as the main reason for the global environmental crisis and in the Plan of Implementation at the Johannesburg conference it was a main concern. In Agenda 21 we read: The major cause of the continued deterioration of the global environment is the unsustainable pattern of consumption and production, particularly in industrialized countries.

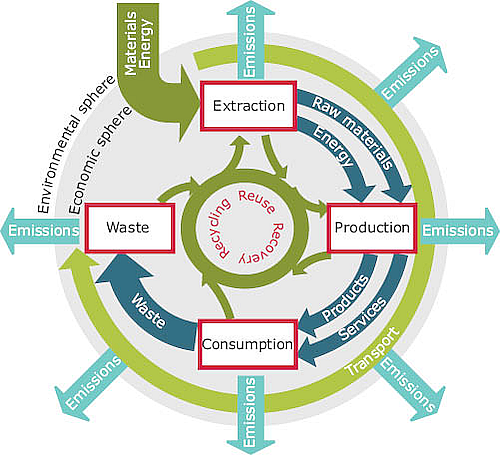

Production is part of a system. It needs to be seen together with the resources extracted, the products produced and how they are used, and finally the waste, which all products eventually will become. This is the life-cycle of a product. In this session on sustainable production and consumption we will cover each of these life stages from resources to waste. Here we will just note that the pattern of production in industrial society is using enormous amounts of natural resources, is often inefficient and leads to waste accumulation. To become sustainable production needs to be much more like what we see in nature: in nature resources are recycled, energy is based on sun, and products are extremely efficient.

Environmental impact along the life cycle is calculated according to well-established methods in a so-called Life Cycle Assessment, LCA. LCA is much used to compare different production methods or products. A classical question to be answered by an LCA is “Is it better to use a reusable glass or a through-away plastic bottle for drinks?” The comparison needs to take into account the resource used for producing the glass bottle including energy, transporting it back to the factory, cleaning it, while the plastic bottle only uses the oil to make plastic. In a classical analysis it turned out that the glass bottle needs to be reused 11 times to be better.

LCA results often show some 10 different parameters such as resource use, energy use, waste, different emissions etc. The difficulty is where to set the system borders, i.e. what to include, since each of the material used in turn have been produced and their effects need to be included. Even if a proper complicated LCA is not conducted each person should consider, be aware of, the life cycle of products. Life cycle thinking is the beginning of a systems approach to production. LCA can be seen as both a management tool and as a way to integrate environmental concern into product development.

"Life-cycle chain from extraction - through production - to consumption and waste.

"Life-cycle chain from extraction - through production - to consumption and waste.

Source: EEA, ETC Sustainable Consumption and Production.

Pollution from industries was long understood as merely a constraint from the environment and thus a burden and a cost for the production. The so-called end-of-pipe approach was used to combat pollution. End-of-pipe means that effluents, emissions and waste are treated to remove pollutants. But eventually it was understood that pollution was rather a sign that the production processes themselves were not working well. The resources should be used for products not pollutants! The change of production processes to non-polluting and resource efficient processes is called cleaner production, CP measures. Cleaner production is in the economic, environmental and social interest of producers and have since the 1990s been implemented in many industries.

The introduction of cleaner production methods, and related methods such as waste minimization, pollution prevention, etc is normally done using a management system. It asks for systematic measurements of the flow of resources, of products and by-products, etc. followed by systematic projects to deal with them, and a follow-up. Management cycles are based on the simple series “plan-do-check-act”, the so-called Deming cycle. One should repeat the cycle, most often each third year, each turn focusing on some important problem. The Environmental Management Systems, EMS, have since the 1990s been standardized to permit external checks, i.e. environmental audits, and the possibilities for certification. The most common EMS system is ISO 14001. ISO stands for the International Organisation for Standardzation; the system is recognised internationally. A company or other actor (such as a university) that has a certification according to 14001 is working systematically to improve its environmental profile; it is not necessarily yet very good in environmental performance, but certainly getting better.

The ideal production scheme should not only be non-polluting. Its products should also be possible to use for a new cycle of production. This is called C2C, or cradle to cradle. Here the resource flow does not lead from cradle to grave (too often the landfill) but rather becomes a new cradle. The resources used by the industry are then old (wasted) products. While the cleaner production methods aims to improve a process to be “less bad”, the C2C approach is to “be good”, that is contribute to the environment. It is not only a vision. Today many hundreds of companies have been certified as C2C companies.

When the outlets from one industry are used as a resource in another it is called industrial symbiosis or sometimes industrial ecology. This pattern of cooperation is most often seen in agriculture, but it can be done in many kinds of industries.

Textile industry in Poland. Photo (CC BY-NC-ND 2.0): Steve McNicholas.

Textile industry in Poland. Photo (CC BY-NC-ND 2.0): Steve McNicholas.

As the effects of pollution and resource depletion have become more serious, the environmental laws of countries have become stronger. In particular European Union law has been of great importance for improving the environmental performance both of business and the public sector. The increasing environmental threats demand new measures to improve the management of economic activities. That, in turn, prescribes the necessity to take into account ecological requirements in production, development of new products, and management of technological processes, as well as personal and financial management.

Materials for session 5a

Basic level

- Read Environmental Management, book 2, chapter 3, pages 59–69: Industry and Industrial History in the Baltic Sea Region.

- Read Environmental Management, book 2, chapter 1, pages 27-46: Industrial Impact on the Environment.

- Read A Sustainable Baltic Region, session 5, chapter 1, pages 5-10: Environmental Challenges for Industry in the Baltic Sea Region.

- Read A Sustainable Baltic Region. session 5, chapter 4, page 32: Life Cycle Assessment - LCA of Dipers.

- Read Environmental Management, book 2, chapter 1, pages 19-25: Introduction: Cleaner Production.

- Read Environmental Management, book 4, chapter 1, pages 19-26: Basics of Environmental Management Systems.

- Watch Cleantech investments in Eastern Europe – NEFCO (YouTube film).

- A presentation by Lars Rydén on: Cleaner Production.

- A presentation by Lars Rydén on: Cleantech Production and Consumption.

- Watch Ecoprint - a film on Ecoprint, a printhouse in Estonia (YouTube film).

- The Story of Stuff - This is a 20-minute, fast-paced, fact-filled look at the underside of our production and consumption patterns (YouTube film).

Medium level (widening)

- Basic concepts

Sustainable Consumption and Production (SCP) Targets and Indicators and the SDGs IISD International Institute for Sustainable Development (UN)

European Sustainable Consumption and Production Policies EU Commission DG Environment (EU) - Read Environmental Management, book 2, chapter 11, pages 155-164: Green Engineering.

- Read Environmental Management, book 2, chapter 12, pages 165-178: Green Chemistry.

- Read Environmental Management, book 3, chapter 5, pages 87-96: Introduction to Life Cycle Assessment.

- Read Environmental Management, book 4, chapter 2, pages 27-35: Overview of Environmental Standards.

- Watch William McDonough author of Cradle to Cradle (YouTube film).

Advanced level (deepening)

- Read Environmental Management, book 2, chapter 4, pages 71-86: Cleaner Production Assessment.

- Read Environmental Management, book 4, chapter 9, pages 85-94: Integrated and Simplified Management Systems.

- Study in some detail two cases – Select from Environmental Management, Book 4: Systems and Certification, Case studies:

Case 1: Kunda Nordic Tsement Ltd.

Case 2: Huta Stali Czestochowa

Case 3: Cologne Wastewater Treatment Plants

Case 4: Gamla Uppsala Buss AB

Case 5: University of Applied Sciences Zittau/Görlitz

Case 6: Municipality of Nacka

Case 7: Nina Printhouse - Study some cases of environmentally clever productions from the Blue Economy (ZERI in Action, Zero Emissions Research Institute).

References

Nilsson, L., Persson, P. O., Rydén, L., Darozhka, S. and A. Zaliauskiene. 2007. Cleaner Production - Technologies and Tools for Resource Efficient Production Environmental Management Book 2, Baltic University Press, Uppsala.

Strahl, J. 1997. A Life Cycle Assessment of Diapers. In: Strahl. J. (ed.). 1997. Sustainable Industrial Production - Waste minimization, cleaner technology and industrial ecology. A Sustainable Baltic Region. Session 5.

Weiß, P. and J. Bentlage. 2006. Environmental Management Systems and Certification. Environmental Management Book 4, Baltic University Press, Uppsala.

Zbicinski, I., Stavenuiter, J., Kozlowska, B. and H.P.M. van de Coevering. 2006. Product Design and Life Cycle Assessment. Environmental Management Book 3. Baltic University Press, Uppsala.